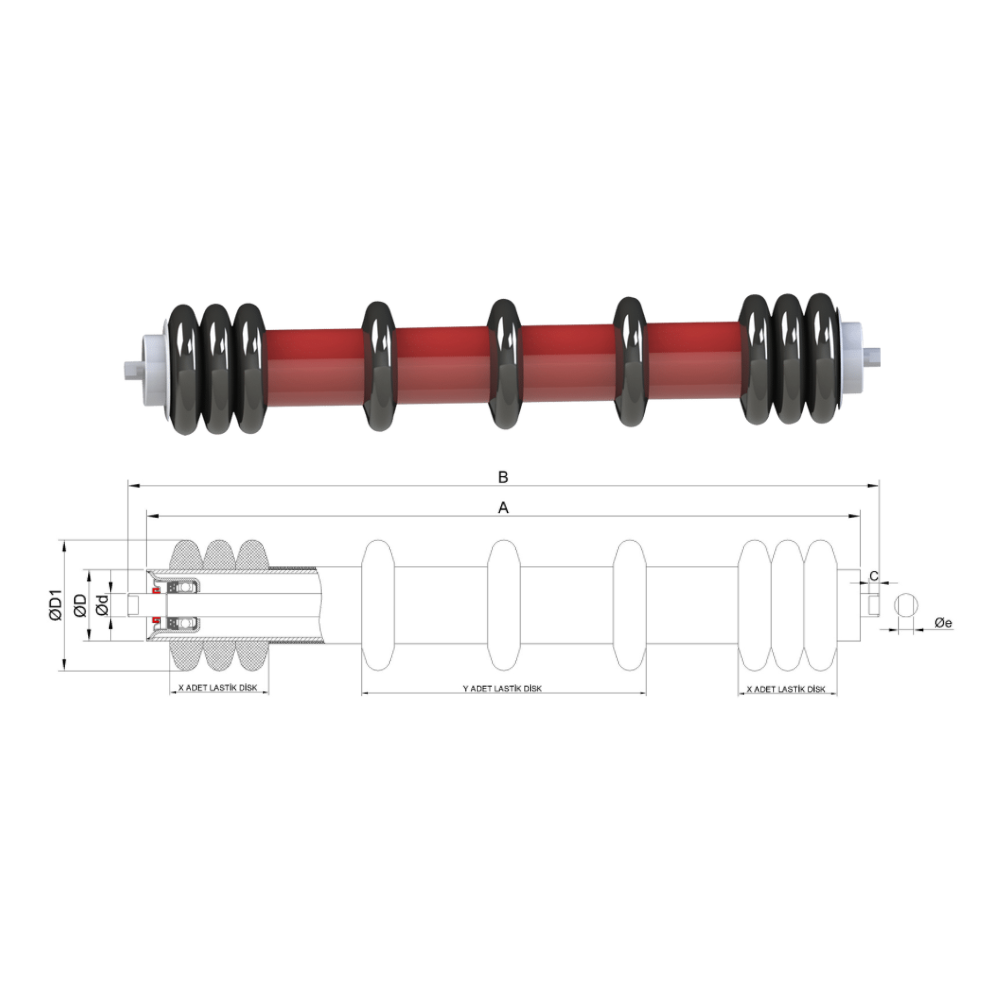

Return Roller

They are used to maintain and support the flow of the belt along the return line. They can be manufactured with rubber discs in case the transported material tends to stick to the tape or has a wear problem.

They can be used for transporting a wide variety of loads, conveying and transferring materials on machinery and assembly lines. Piece goods, angular or cylindrical goods, boxed, packaged products can be transported horizontally or inclined.

The products are conveyed on rollers placed at regular intervals on the conveyor frame. They are divided into two as driven and free-rolled according to their working style.

Material transport in free roller conveyors is provided by height difference, first speed system, human or machine pushing power. In these conveyors, the force is applied directly to the load. The rollers rotate with the friction of the load making translational motion along the conveyor bed.

In driven roller conveyors, on the other hand, the rollers are driven by the chain that works with the motor-reducer system and goes around the conveyor. Driven conveyor rollers are rotated around their axis by a motor. The motion is transmitted to the transported trowel by friction.

The spacing of the rolls, the roll diameters and the material are also determined by the type of product to be transported. Galvanized, rubber or PVC coated rolls are designed for customer use. Usage area and capacity vary according to the purpose of use.

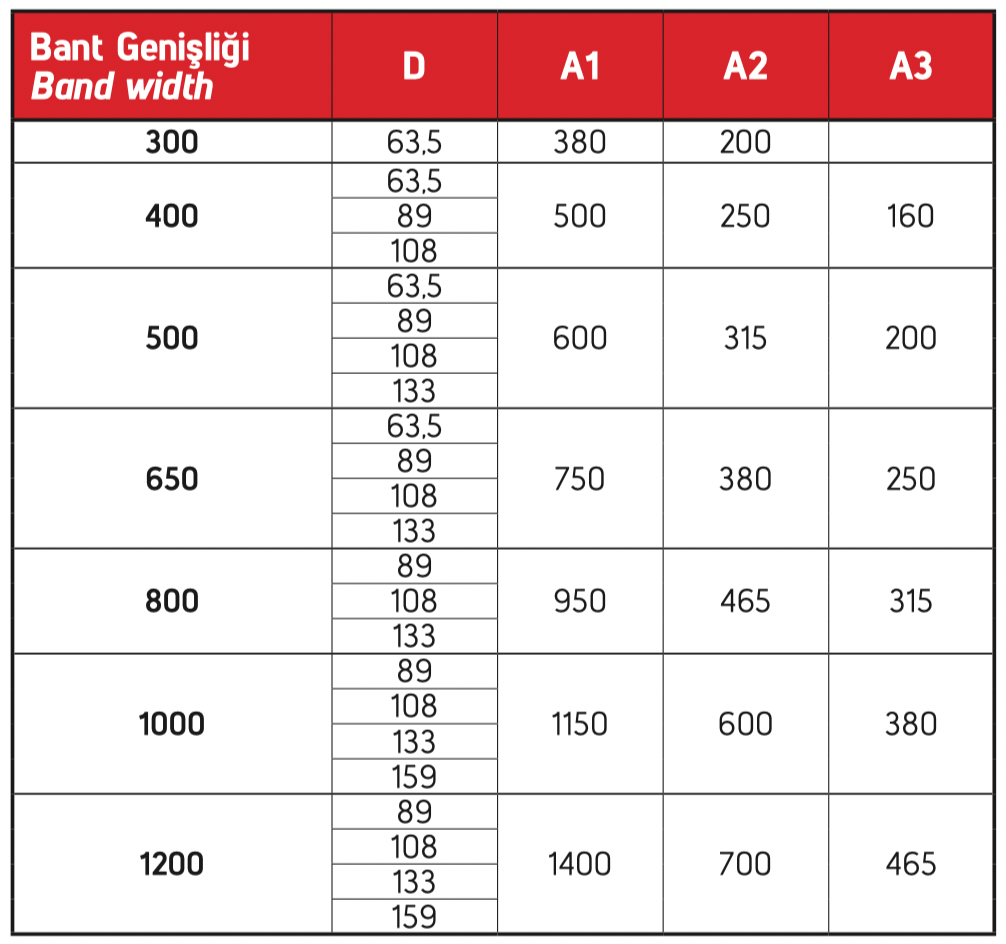

* Shaft diameters are 12-15-20-25-30-40-50mm.

* Production is made up to 3000 mm wide bands.

* 6000 series bearings are used.

* For details contact us.

Why Pres-san?

Trustworthy

Technological

Quality

Spherical

Main features of Pres-san products

- No maintenance required

- Sensitive production with CNC machine to ensure bearing house compatibility and spindle sensitivity

- Labyrinth and dust seals are blocking 100% of dust and water

- Spindle wrench flat and pipe heads are processed simultaneously to ensure parallelism and accuracy

- Double-sided radius roll production that does not damage the band

- Deep drawing in roll covers without thinning the sheet thickness in accordance with the technique

- Concentricity tolerance is in compliance with DIN standards